TB 1--1520--237--20--232

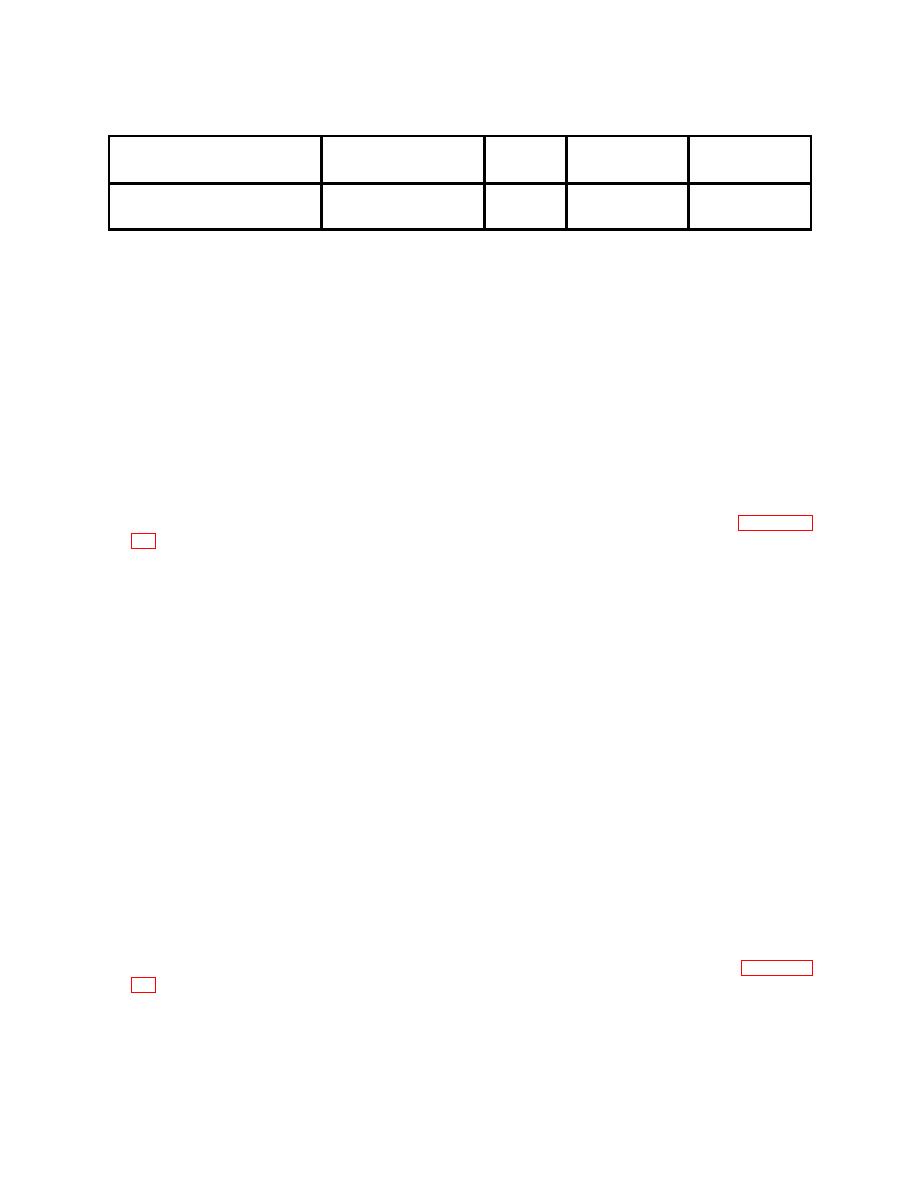

Nut

MS21244-12

14

.63

.82

Nut

MS21244-14

1

.11

.11

5310-00-108-2539

Total Cost per Aircraft (UH-60A) = 9.66

Total Cost per Aircraft (UH-60L) = 0.88

d. TB/MWOs to be applied prior to or concurrently with this inspection. N/A.

e. Publications which require change as a result of this inspection. A copy of this TB will be inserted

in the appropriate TM as authority to implement the change until the printed change is received.

(1) TM 1-1520-237-23-6:

(a) The following paragraphs will be changed as indicated below;

Para 11-4-91.1.3, Install Forward Control Rod

Para 11-4-92.1.3, Install AFT Control Rod

Para 11-4-93.1.3, Install Lateral Control Rod

Para 11-4-94.1.3, Install Long Control Rod

Para 11-4-95.1.3, Install Swashplate Links

Para 11-4-100.1.3, Install Walking Beam

Para 11-4-101.1.3, Install Forward Bellcrank

(b) Add the following procedural prior to step b. in each task identified IAW paragraph

12.e.(1) (a) above.

CAUTION

If resistance or binding of the retaining ball mechanism is observed when pin is actuated, do not apply

corrosive preventive compound to free the mechanism. The inner core of the bolt is corroded and must

be rejected.

"Prior to installing the special self-retaining bolt, depress the retaining pin and fill the bolt with corrosion

preventive compound (CPC) , Item 114, Appendix D. Apply CPC through one ball hole (while working

the retaining pin) until excess is seen at the opposite ball hole. Rotate the bolt 180 degrees and repeat

procedure at the second hole. Spray CPC into the cotter pin hole. While working retaining pin, apply

CPC at the pin hole in the bolt head and into the hole at the threaded end of the bolt. Lightly wipe excess

CPC from the threads and the retaining ball area. Apply CPC Item 109, Appendix D, to the exterior retain-

ing ball area and threads."

(c)

(2) TM 1-1520-250-23-5:

(a) The following paragraphs will be changed as indicated below;

Para 11.25.23, Install Forward Control Rod

Para 11.25.24, Install AFT Control Rod

Para 11.25.25, Install Lateral Control Rod

Para 11.25.26, Install Long Control Rod

Para 11.25.27, Install Swashplate Links

Para 11.26.4, Install Walking Beam

Para 11.26.5, Install Forward Bellcrank

(b) Add the following procedural step prior to step b. in each task identified IAW paragraph

12.e.(2) (a) above.

CAUTION

If resistance or binding of the retaining ball mechanism is observed when pin is actuated, do not apply

corrosive preventive compound to free the mechanism. The inner core of the bolt may be corroded and

must be rejected.

8

Previous Page

Previous Page