TB 1--1520--237--20--230

(b) Adjust the pin as necessary IAW TM 1--1520--237--23, paragraph 5--3--9.1 or TM

1--1520--250--23, paragraph 5.17.1.1. If the pin is conforming after adjustment, reuse the pin.

(c) If pin cannot be adjusted --

(1) Immediately replace the discrepant Main Rotor Blade Expandable Pin.

(2) Submit a CAT 1 QDR against the discrepant pin. Include the serial number (SN),

Time Since New (TSN), and Time Since Last Installed (TSLI) for the following in block 22 of the QDR;

"Spindle Assembly, Main Rotor Blade, Main Rotor Blade Cuff, Main Rotor Blade Expandable Pin".

10.Supply/Parts and Disposition.

a. Parts required -- Items cited in paragraph 12c may be required to replace defective items, or items

removed due to defective parts.

b. Requisitioning instructions -- Requisition replacement parts using normal supply procedures. All

requisitions shall use project code (CC 57--59) "XDI" (X--RAY DELTA INDIA).

NOTE

Project code "XDI" is required to track and establish a data base of stock fund expenditures in-

curred by the field as a result of SOF actions.

c. Bulk and Consumable Materials. -- As required by the H--60 Main Rotor Hub Spindle Ultrasound NDI

procedure. The Couplant provided with the P/N NEC--8102 NDI kit is sufficient to only inspect one aircraft.

Refill for the Couplant is:

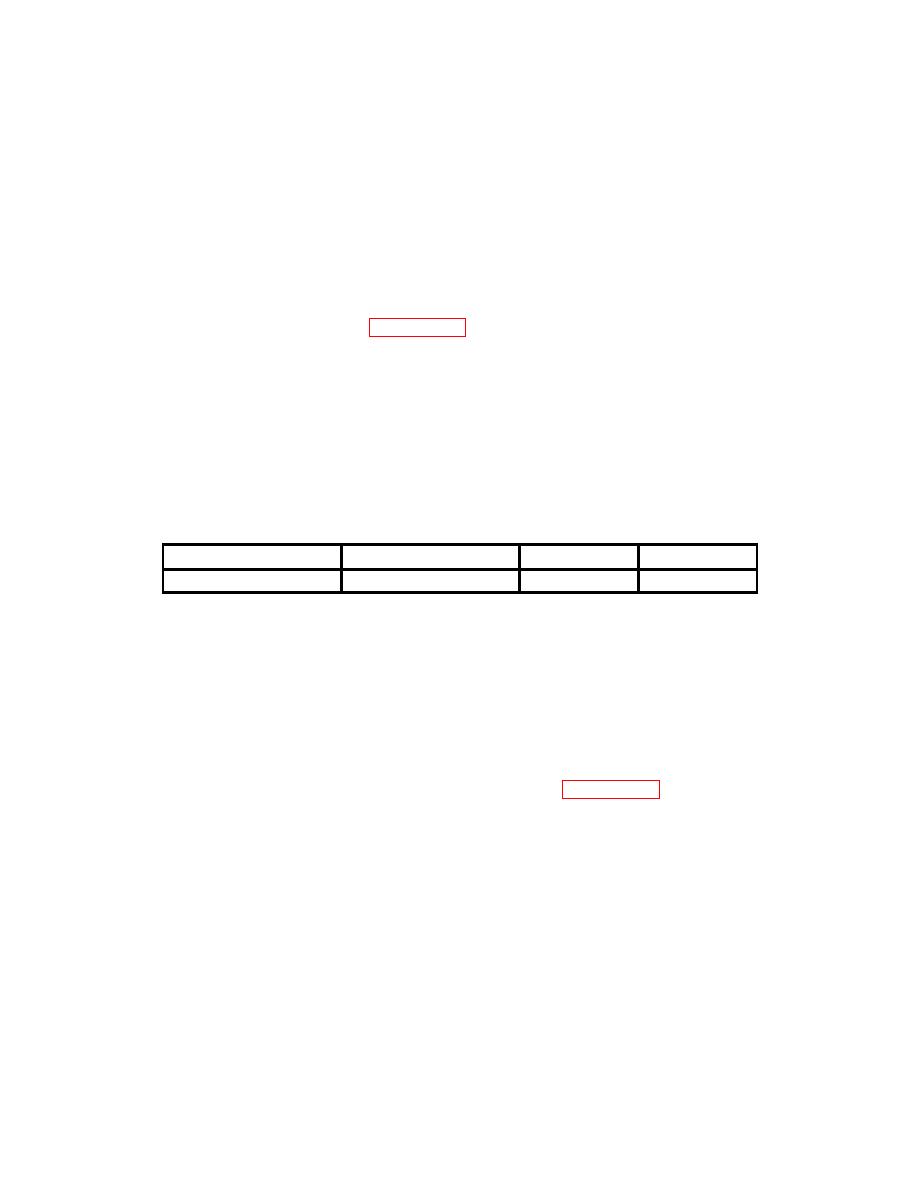

NOMENCLATURE

NSN

SIZE

COST

Ultrasound Couplant

6850--01--157--4348

1 Gallon

.59

d. Disposition -- Submit QDR on discrepant Spindle Lug or broken Expandable Pin. Hold exhibit pend-

ing disposition instructions.

e. Disposition of Hazardous Material -- IAW Environmental Protection Agency directives as implement-

ed by your servicing environment coordinator (AR 200--1).

11.Special Tools, Jigs and Fixtures Required.

a. Ultrasound system Branson USD 15S or equivalent.

b. Ultrasound inspection kit P/N NEC--8102. The source for the inspection kit is NDT Engineering Cor-

poration, 19260 Russel Road, Kent, WA, (253) 872--3565. Additional / Replacement sensors must be or-

dered directly from the kit manufacturer. Contact the Logistics POC in paragraph 16b regarding the availabil-

ity of extra kits.

12.Application.

a. Category of Maintenance -- AVUM / AVIM

(1) Aircraft downtime required to accomplish all 10 hour / 14 day inspection will be charged to

AVUM.

(2) Aircraft downtime required to accomplish the NDI Inspection of the main Rotor Spindle Lugs

will be charged to AVIM.

b. Estimated Time Required --

(1) NDI Inspection --

(a) Main Rotor Blade Removal / Install -- Total of 1.2 man--hours per Main Rotor Blade using

3 people.

(b) NDI Inspection (after blade removal) -- Total of 0.7 man--hour per spindle using 1 person.

5

Previous Page

Previous Page